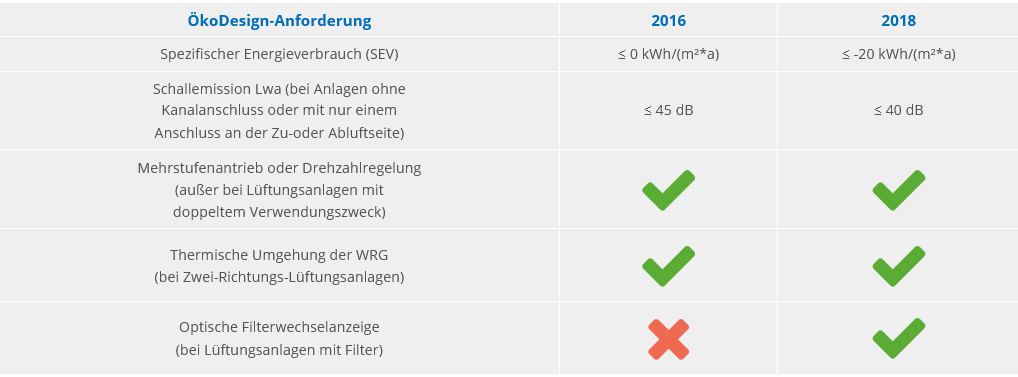

Since 2016, the EU has been regulating the basic requirements for domestic ventilation units in its member states with the EcoDesign Directive. In 2018, it tightened the requirements.

What rules does the EU EcoDesign Directive lay down?

The current requirements according to the EU EcoDesign Directive

EU Regulations 1253/2014, which regulates the requirements for the environmentally friendly design of ventilation systems, and 1254/2014, which clarifies the labeling of the energy consumption of domestic ventilation units, have been in force since 2016. According to EU legislation, manufacturers must provide most domestic ventilation units with an ecodesign label and provide open information about the unit’s characteristic values. In order to provide comprehensive information about domestic ventilation appliances in our domestic ventilation info portal, we have been providing information about the ecodesign and the respective labels on the appliance pages since 2016.

At the turn of the year 2018, the requirements for domestic ventilation units were further tightened in accordance with Annex II of Regulation No. 1253/2014. Accordingly, the following specific requirements have applied since January 1, 2018:

a) the specific energy consumption calculated for an average climate must not exceed -20 kWh/(m²-a),

b) for units without duct connection spigots, including those that are to be fitted with a duct connection on either the supply air or extract air side, LWA must not exceed 40 dB,

c) all ventilation units, except dual-purpose units, must be equipped with a multi-stage drive or speed control,

d) all bidirectional ventilation units must have a thermal bypass device,

e) ventilation units with a filter must be equipped with a visual filter change indicator.

Residential ventilation units that do not comply with the stricter ecodesign requirements may no longer be sold in the EU. We explain the individual requirements below.

Reduction of the maximum permitted specific energy consumption (SEV)

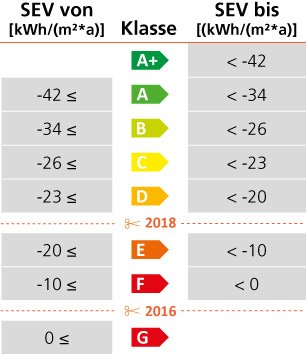

The specific energy consumption (SEV) of controlled domestic ventilation is the most important parameter on the ecodesign labels. Based on the SEV in an average climate, as is the case in Germany for example, appliances are divided into energy efficiency classes from A+ (highest efficiency) to G (lowest efficiency).

To calculate the SEV, the comprehensive formula takes into account environmental factors and physical properties as well as various features and configurations of the ventilation unit. The specific electrical input power of the unit and the recovery of heating energy from the heat exchanger integrated into the ventilation unit are the most important variables.

The type of heat exchanger (recuperative or regenerative), the control of the fan, the type of control of the appliance (demand control, time control or manual control) and the general typology (whether the appliance distributes air with or without ventilation ducts) also play a role.

The calculated SEV is generally a negative value, as it is intended to show the possible savings in primary energy per year per square meter of living space through the use of a domestic ventilation unit in the living space compared to the operation of conventional heating methods. The lower the value, the more primary energy can theoretically be saved by the appliance.

The graphic shows how the new minimum requirements affect the energy efficiency classes. Home ventilation units that fall under classes E, F and G may no longer be sold in the EU from January 1, 2018. It should be noted that the requirements only apply to domestic ventilation units that consume more than 30 W of total electrical power per air flow direction.

The SEV values of classes E, F and G are achieved by supply or exhaust air devices without heat recovery, which only save heating energy by ensuring controlled ventilation in the living space. However, the vast majority, if not all, of these appliances do not fall under the regulation due to their low electrical output or other characteristics. Supply/exhaust air devices with heat recovery generally achieve classes B to A+ and are therefore not affected by the stricter requirements.

Need for multi-stage drive or speed control of the fans

Fans should always supply sufficient air to the interior to meet the acute requirements in the living area. Only with sufficient air exchange can both building protection and the health of the occupants be ensured. In order to run particularly efficiently and not consume energy unnecessarily, however, no more air should be conveyed than is necessary for the current conditions in the living space. It is important that the fans in the home ventilation unit are equipped with sufficient ventilation stages or with infinitely variable speed control in order to adapt the air exchange to the actual conditions.

In the ecodesign for domestic ventilation units, this aspect is taken into account on the one hand by including the so-called x-value as a parameter in the calculation of the SEV. This only applies as long as the device has better control options than purely manual adjustability by the user. The more operating speeds the fan can operate at, the lower the calculated annual power consumption of the appliance, with infinitely variable speed control being the most energy-efficient.

Secondly, since 2016, no appliances may be sold in the EU that can be operated at less than three fixed speeds plus speed 0 (off).

Reduction of the maximum permitted sound level LWA

In order to maintain the living comfort of the residents and prevent noise pollution from the ventilation unit, the proper operation of a system must be realized without noticeable noise emissions into the living space. In the case of centralized systems with ducted supply and extract air flows, this is mainly achieved through standard-compliant and proper planning, installation and maintenance by the specialist installer. In the case of decentralized devices that are directly adjacent to interior rooms in at least one air flow direction, the emission of sound through the housing must not affect the occupants during normal operation.

With the tightening of EU Regulation 1253/2014, the EU Commission has agreed that such domestic ventilation units may not emit more than 40 dB (A) of sound emissions into the interior since January 1, 2018. The sound power level emitted by the housing at the reference air flow rate is used to assess the sound power for the ecodesign requirements. The reference air volume flow is the air volume flow that can be driven by the domestic ventilation unit and is at 50 Pa (for units with duct connection) or a minimum pressure (for units without duct connection) closest to, but at least 70 percent of the highest air volume flow. This means that the sound power of the home ventilation unit when ventilating at the highest level can be above the guide value specified on the ecodesign label.

It should also be noted here that many of the devices for which the limit values could become critical are not affected by the ecodesign requirements due to their basic configuration. In most cases, supply or exhaust air systems suitable for domestic ventilation without duct connection spigots or with spigots in only one air flow direction have a total electrical output of well below 30 W per air volume flow.

Thermal bypass device required

On particularly hot days, especially in summer, heat recovery by the domestic ventilation unit may be undesirable as it would lead to further heating of the living area. For this reason, supply/extract air units are usually equipped with a thermal bypass – often referred to as a summer bypass – which prevents the transfer of heat from the extract air to the supply air.

According to the ecodesign requirements of Regulation (EU) No 1253/2014, bidirectional residential ventilation units, i.e. supply/extract air handling units placed on the market in the EU, must have a thermal bypass device. Such a device is defined in the regulation as: “[…] any solution that bypasses the heat exchanger or controls its heat recovery performance automatically or manually, which does not necessarily require a physical bypass duct.”

The thermal bypass of heat recovery can therefore be realized by various types of devices. Many appliances have a bypass function that can be activated manually or automatically, after which the outside air flow is routed past the heat exchanger so that the supply air is not heated up. Another solution, which was often installed in older appliances, is a summer box. The user installs this manually in the appliance as required in order to redirect the air. Heat recovery can also be reduced or completely prevented, for example if the ventilation is switched off temporarily, by configuring the air flow or impeller speed depending on the temperature. With decentralized changeover units, summer operation is ensured by one unit constantly conveying the supply air and another constantly conveying the extract air without the air directions switching.

Equipping the ventilation system with an optical filter change indicator

Since the beginning of 2018, ventilation systems with at least one filter installed to protect the interior and the device itself from contamination must be equipped with a visual filter change indicator. In principle, every domestic ventilation unit should have a filter for air purification, as hygiene and subsequently ensuring the health of residents are among the most important functions of these devices. The devices themselves should also be protected from dirt.

Most supply/exhaust air appliances therefore have a medium to fine air filter that cleans the air supplied to the interior so that dust, pollen and fine dust are filtered out in sufficient quantities. In addition, there is often a coarse filter in the exhaust air duct in front of the heat exchanger to prevent the appliance from becoming dusty. For the same reasons, at least one filter should also be installed in pure supply or exhaust air appliances

As the filters themselves become dirty during operation, which results in a reduction in the air volume flow rate or an increase in electricity costs, they must be replaced with new, clean filters regularly, once or twice a year for most filters. Filter contamination is monitored by the appliance, for example by counting the operating hours or measuring the pressure loss. If the appliance deems a filter change to be necessary, it indicates this acoustically or visually in most appliances, whereby an optical filter change indicator must be installed in all new appliances since 2018 in accordance with the new requirement.

However, the ecodesign regulations for domestic ventilation appliances do not define where this visual indication should take place. It is possible to display the required filter change directly on the device, on the display in the living room or, in the case of computer, tablet or smartphone-controlled ventilation devices, via a notification in the program or app. The former option is less suitable for regularly checking the filter status due to the fact that supply/exhaust air units are usually installed in a separate technical room, the basement or in the attic.